Cold UV Curing System

victory-datasheet_2025_cold-uv-curing.pdf

Cold UV Curing System

VICTORY Cold UV curing system is more than you think. In the last 20 years, VICTORY is focus on researching and developing cold UV curing to help our clients improving their printing speed and quality.

At Victory, we specialise in cutting-edge UV curing solutions for the printing industry. Our Cold UV Curing technology is revolutionising the way you print, offering tangible benefits that go beyond traditional heating methods.

What is Cold UV curing and why should you use it for printing?

Compared with other heating methods, cold UV curing reduces the temperature required and can improve printing quality and accuracy. Working with cold UV curing temperatures also helps improve your UV lamp bulb ‘s working lifetime; our patented design lamp head, runs for over 2000 hours! Lowering your curing temperature is good for curing UV lacquer on thermal sensitive materials, for example, on printing base film such as PET film.

Enhanced Printing Quality

By reducing curing temperatures, Cold UV Curing ensures superior precision and clarity, even on heat-sensitive materials like PET films. The result? Flawless, high-accuracy prints every time.

Extended UV Lamp Lifetime

Thanks to our proprietary lamp head design, our UV lamp bulbs deliver exceptional durability, boasting a lifespan of 2,000 to 3,000 hours. This means fewer replacements, less downtime, and more savings for your business.

Versatility Across Materials

Whether you’re curing UV lacquer on delicate thermal-sensitive substrates or achieving consistent results on a wide range of materials, our low-temperature curing technology ensures optimal performance without compromising on quality.

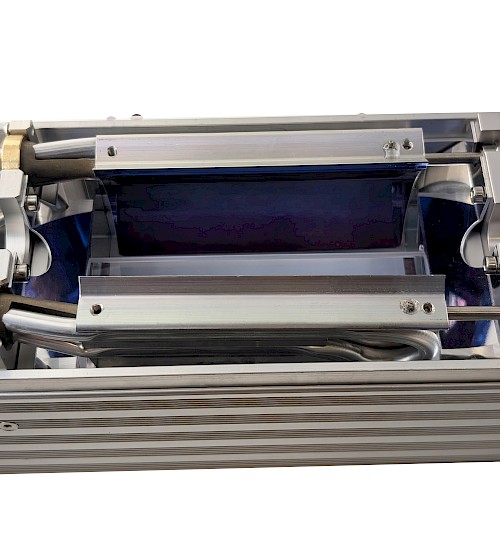

Easy to install UV cold curing

Our UV curing systems use "Plug & Play" design. A complete system includes 1 set of UV lamp head/house, 1 set of Ballast with a control unit, 1 set of Integrated PLC system with touch screen, which shows all lamp working information.

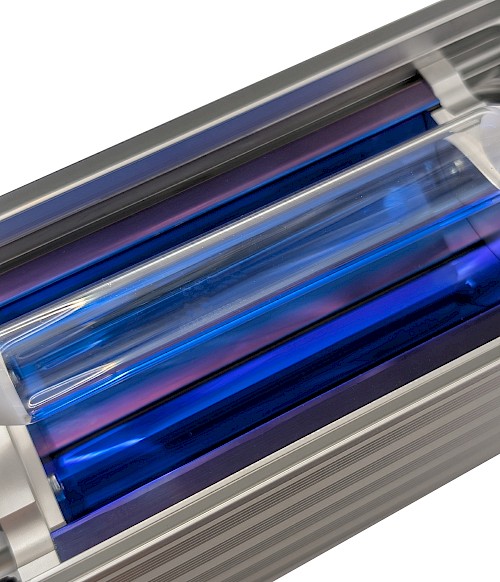

Lower curing temperature

All Victory UV lamps are built in our patern design, lamp house, which uses special heat absorbing coating reflector which can absorb 90% of IR caused by lamp lighting; transfering the heat to the in-built cooling channel and lowering the curing temperature.

Higher-efficiency UV Energy Output

More than 60% output of a UV lamp is IR, meaning you can only get 80w/cm UV energy from a 200w/cm UV lamp. Our Victory patent technology, UV lamp head design, increases UV curing efficiency by 30% by focusing UV light to a narrow line.

Better Uniformity

Victory UV lamps provide high uniformity for UV energy output. Our specially designed lamps can reach more than 90% for all curing area.