Curing Lamps and Systems

Search

Search using your product name or manufacturer code to find compatible lamps.

Medium Pressure UV Lamps

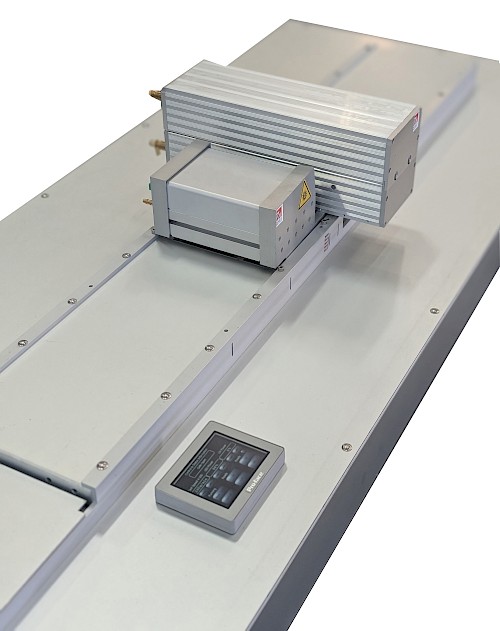

Cold UV Curing System

UV LED System

Air Cooled UV LED System

Speedy Ink Testing System

UV LED Embosser

Hybrid UV System

Victory supplies advanced UV curing lamps and systems trusted by manufacturers, printers, and OEMs worldwide.

With over 34 years of experience in specialist lighting, we deliver high performance UV solutions & products for applications in printing, packaging, coatings, adhesives, electronics, health and hygiene, security, and more.

Whether you need replacement UV lamps or UV LED curing systems, Victory offers durable, hand-sealed products designed for demanding production environments.

Product Finishes

Medium Pressure Mercury

With especially high emissions in the UV-C range, Victory mercury lamps provide curing for printing processes that use pigmented inks and UV varnishes.

Metal Halide Gallium

Metal halide, gallium doped lamps have high emissions in the longer UV wavelengths and are suitable for thick layered and pigmented varnishes which require penetrative curing.

Metal Halide Iron

Metal halide, iron doped lamps have a high UV-A and UV-B content, and so are the right choice for curing thickly layered inks.

While traditional medium-pressure and metal halide lamps provide broad-spectrum UV curing, Victory’s UV LED curing systems offer precise wavelength control and energy efficiency, making them ideal for modern printing and coating processes.

What is UV Curing?

UV curing is a process that uses ultraviolet light to rapidly cure inks, coatings and adhesives. Unlike heat-based drying methods, UV curing triggers a photochemical reaction that creates a strong cross-linked polymer network.

UV LED curing systems operate by emitting light in a specific UV wavelength, initiating a photochemical reaction that cures without heat damage. Compared to traditional UV lamps, UV LED curing systems are energy-efficient, long-lasting and ideal for high-speed industrial applications.

Originally developed and introduced in the 1960’s, UV Curing technology has streamlined and increased automation in many areas of the manufacturing sector. Unlike other technologies such as infrared curing, UV is considered a low temperature process and is therefore ideal for using on substrates that are unsuitable for use with heat producing products.

As cure occurs via polymerisation rather than evaporation, processing times are dramatically improved without the need for drying ovens and large amounts of racking. This faster drying time also helps to reduce flaws and errors as well as improving consistency.

As UV energy has unique interactions with many different materials, Ultraviolet curing can produce unique products that have characteristics that can not be produced via other means. This has made the technology essential for certain industries where changes in strength, durability, chemical resistance and more are required.

Find out more about UV Curing Systems

Want to find out about how UV curing systems work and why they're so efficient? Check out our detailed What is a UV Curing System? article.

What are the benefits of UV curing systems?

- Faster curing times → no drying ovens or long racking periods.

- Low heat output → ideal for plastics, films, and heat-sensitive materials.

- Higher consistency → fewer defects and improved product quality.

- Durability → better strength, chemical resistance, and wear protection.

- Energy efficiency → reduced power consumption vs infrared curing.

If you're looking to integrate UV curing systems into your manufacturing process, see How UV Systems Fit into Existing Production Lines.

UV Curing Technologies

Choosing the Right UV Curing System

Selecting the optimal UV curing technology depends on your substrate, coating type, and production speed requirements. Traditional medium pressure lamps are ideal for broad-spectrum curing and heavy coatings, while UV LED and cold UV systems offer energy efficiency, precise wavelength control, and low-heat operation for sensitive materials. Understanding these differences ensures faster curing, consistent finishes, and long-term reliability for industrial and commercial applications.

UV LED Curing Systems

Modern UV LED systems deliver precise wavelength control, long lifetime, and low energy use.

- Up to 70% more energy-efficient than traditional lamps.

- No warm-up time → instant on/off.

- Ideal for high-speed printing and coating lines.

Cold UV Curing Systems

Designed for heat-sensitive substrates, cold UV curing minimises thermal impact.

- Prevents warping or shrinkage.

- Delivers uniform curing.

- Suitable for flexible packaging, electronics, and delicate materials.

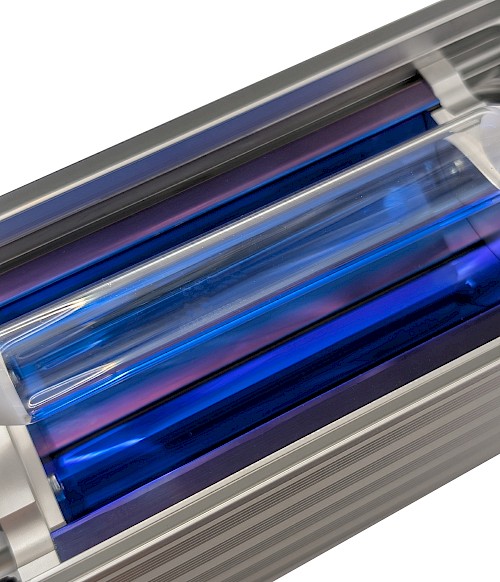

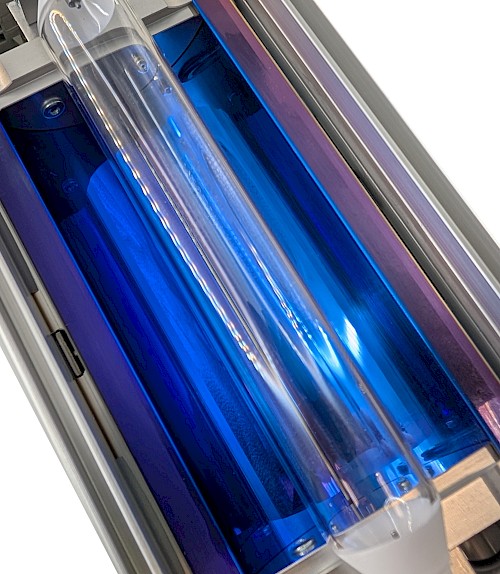

What is a Cold UV Curing System?

Cold UV curing systems are designed to cure inks, coatings and adhesives without generating significant heat. Unlike traditional medium pressure UV lamps, cold UV systems use specialised lamps that emit UV light at lower temperatures, making them ideal for heat-sensitive substrates such as plastics, films and delicate packaging materials.

Key benefits of Cold UV Curing Systems:

- Low heat output: Prevents warping, shrinkage, or substrate damage.

- Energy-efficient: Consumes less power compared to medium pressure systems.

- Consistent curing: Provides even polymerisation across the surface for high-quality finishes.

- Versatile applications: Suitable for both printing and coating processes that require minimal thermal impact.

Cold UV systems are particularly valuable in industries where substrate integrity is critical, such as flexible packaging, electronics and high-end graphic printing.

Medium Pressure UV Lamps

Victory’s medium pressure mercury and metal halide lamps provide broad-spectrum curing power:

- Mercury UV lamps → strong UV-C output, ideal for pigmented inks and varnishes.

- Gallium-doped lamps → longer UV wavelengths, for thick coatings and pigmented varnishes.

- Iron-doped lamps → UV-A and UV-B rich, best for curing layered inks.

Hand sealed for assured quality

Our hand-sealed and capillary-sealed lamps ensure the highest quality for both traditional UV lamps and advanced UV LED curing systems, offering precision and reliability for demanding production environments.

Capillary sealed UV lamps — also known as roll sealed — are made by hand, using the vacuum within the lamp to form accurately the heated quartz around the conducting foil. This method allows for short, specialised, high quality production runs such as for high current double foil designs.

Industries That Benefit from UV Curing

- Printing & Packaging

- Electronics

- Automotive & Aerospace

- Security Printing

- Health & Hygiene

UV Curing Systems and Lamps Frequently Asked Questions

Q: What is a UV lamp used for in industry?

A: Industrial UV lamps are used to cure inks, coatings, adhesives and resins, as well as for surface treatment and sterilisation processes where fast, controlled curing is required.

Q: How does ultraviolet curing work?

A: UV curing uses ultraviolet light to initiate a chemical reaction in specially formulated materials, causing them to harden or cure instantly without the need for heat or long drying times.

Q: How does UV curing compare to infrared curing?

A: UV curing is a low-temperature process that uses light rather than heat, making it faster and safer for heat-sensitive materials.

Q: What’s the difference between medium pressure UV and UV LED systems?

A: Medium pressure lamps provide broad-spectrum curing, while UV LED systems offer specific wavelengths, longer life, and greater energy efficiency.

Q: How long do UV curing lamps last?

A: Lifetimes vary by type, but UV LED systems can last up to 20,000 hours, much longer than traditional lamps.

Q: Which industries benefit most from cold UV curing?

A: Flexible packaging, electronics, and delicate substrates where heat could cause damage.