Ultraviolet, UV Technology

Ultraviolet (UV) technology uses light rays with wavelengths shorter than visible light, allowing it to perform a wide range of tasks. It is commonly used for sterilisation, curing, and disinfecting in industries like healthcare, food processing, and manufacturing. UV technology provides efficient solutions for applications like water purification, mold elimination, and plastic forming. It is also utilised in sectors such as automotive, textiles, aerospace, and printing for various processes, including drying and surface treatments. UV's versatility makes it a vital tool across many industries.

UV technology is also utilised in curing inks, coatings, and adhesives, providing fast, efficient results. Additionally, UV lamps are often applied in air purification systems and germicidal applications to ensure a cleaner and safer environment. As technology advances, UV solutions continue to enhance efficiency across multiple sectors.

UV technology offers powerful and efficient curing by using ultraviolet light to instantly harden coatings, inks, and adhesives. This rapid curing process ensures high-quality, durable finishes while reducing production times.

Victory Lighting’s R&D facility is committed to innovation in infrared technology. By investing in cutting-edge research, we help develop advanced solutions tailored to specific industry needs, driving efficiency and sustainability in heating, curing, and beyond.

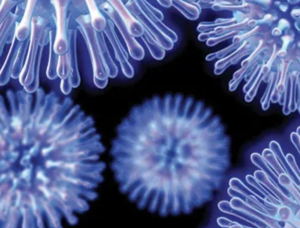

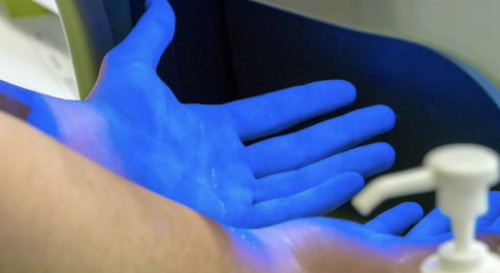

UV technology is highly effective in eliminating harmful microorganisms, including bacteria, viruses, and fungi. Its germicidal properties make it an ideal solution for disinfecting water, air, and surfaces.

UV Technology: Applications and Benefits Across Industries

UV technology is revolutionising industries with efficient and precise solutions that enhance productivity and outcomes across various sectors. In dentistry, it accelerates curing materials for more effective treatments, while in the automotive industry, it ensures superior finishes by drying and curing coatings. The food processing sector benefits from UV sterilisation to extend shelf life, and water purification systems use it to eliminate harmful pathogens for safe consumption. From speeding up ink drying in printing to improving fabric durability in textiles, UV technology is indispensable, even in specialised applications like aerospace and bespoke manufacturing projects.

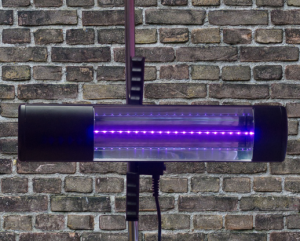

Germicidal Lamps

UVC light works by disrupting the DNA or RNA of microorganisms. When UVC light penetrates the cells of these organisms, it causes thymine dimers to form in their DNA or RNA, disrupting their replication process. This effectively renders the microorganisms inactive or kills them, preventing them from reproducing and spreading.

Paint Dryers

The UV paint dryer offers very fast drying times, making it an ideal solution for curing paints, varnishes, and other specialist coatings. Unlike more conventional methods, UV curing technology can dry coatings in a matter of minutes. These fast-drying times help ensure a more consistent finish across the substrate, as dust and other foreign objects have less opportunity to contaminate the coating.

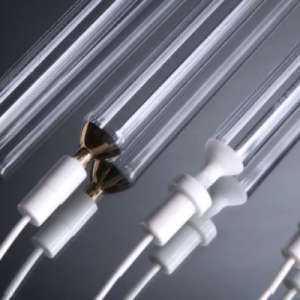

Medium Pressure UV

Victory medium pressure and metal halide UV light sources are highly versatile and play a crucial role across a wide range of industries. These UV light sources are especially effective in applications such as curing, disinfection of air and water, and the printing industry. In the curing process, medium pressure UV light sources are used to rapidly cure coatings, inks, and adhesives.

How to Select the Best UV Lamps for Sterilisation

Ultraviolet (UV) lamps are an effective and widely used solution for sterilisation across industries such as healthcare, water treatment, food processing, and manufacturing. By emitting UV-C light (200-280 nanometers), these lamps deactivate microorganisms by damaging their DNA or RNA, rendering them incapable of reproduction.

Read the full article on How to Select the Best UV Lamps for Sterilisation.

How UV Technology Enhances Sterilisation, Curing, and Disinfection

UV technology uses ultraviolet light, particularly UV-C wavelengths, to provide efficient and reliable solutions of sterilisation, curing and disinfection across multiple industries. By disrupting the DNA or RNA of microorganisms, UV-C light prevents replication and effectively neutralises harmfil pathogens. Beyond sterilisation, UV technology accelerates industrial curing processes and improves overall product quality, making it a versatile tool for businesses and manufacturers looking for both safety and efficiency.

UV Technology in Air and Water Purification

UV technology is widely used in air and water purification systems to maintain safe and clean environments. In air purification, UV-C light targets airborne bacteria, viruses, and mold spores, reducing the risk of contamination in offices, hospitals, and public spaces. For water treatment, UV technology provides chemical-free disinfection, eliminating harmful microorganisms without affecting water quality. By integrating UV technology into purification systems, facilities can achieve consistent sterilisation while meeting health and safety standards.

UV Technology for Industrial Curing Processes

In industrial settings, UV technology is used for curing paints, coatings, adhesives, and inks. UV-C and medium-pressure UV lamps rapidly harden coatings, reducing production times and ensuring uniform finishes. This precision allows manufacturers in sectors like automotive, printing, textiles, and electronics to maintain high-quality standards while improving operational efficiency. Using UV technology for industrial curing not only speeds up production but also reduces energy consumption compared to traditional methods.

The Role of UV Technology in Healthcare and Food Processing

Healthcare and food processing industries benefit greatly from UV technology due to its proven sterilisation and disinfection capabilities. In healthcare, UV-C light is employed to disinfect surgical tools, equipment, and patient rooms, lowering the risk of hospital-acquired infections. In food processing, UV technology ensures that surfaces, packaging, and water used in production remain free from harmful bacteria and viruses, extending shelf life and maintaining product safety. By adopting UV technology, these sectors can uphold strict hygiene standards while enhancing operational reliability.