Specialists In

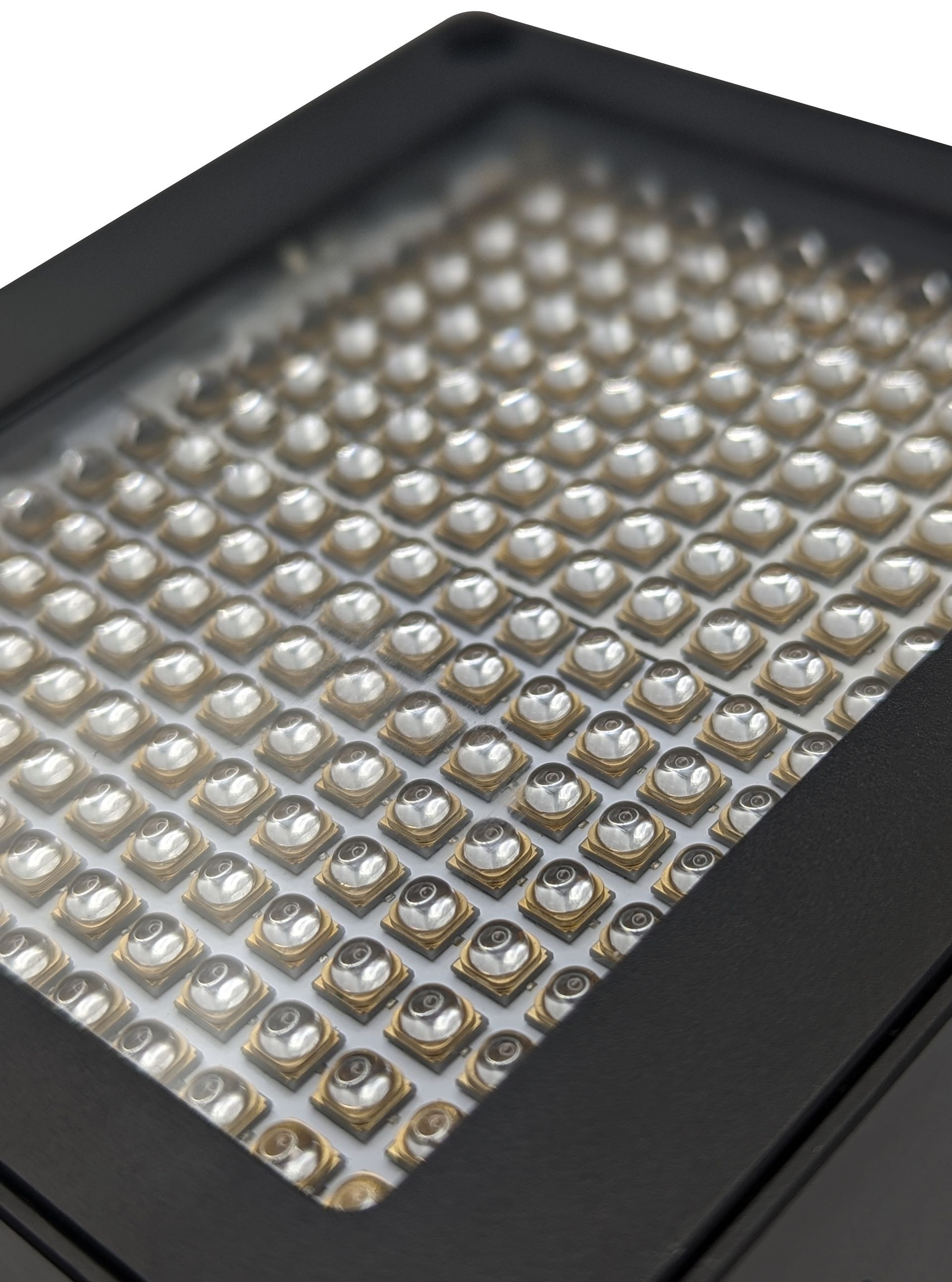

Infrared for plastic deburring

How can Infrared Lamps help in Plastic Deburring?

Infrared lamps have revolutionized the deburring process, offering remarkable advantages that traditional methods can't match. Here are just a few reasons why you should consider incorporating them into your plastic manufacturing operations:

✅ Enhanced Efficiency: Infrared lamps provide focused and intense heat, enabling rapid and precise deburring. Say goodbye to manual sanding or filing, and hello to improved productivity!

✅ Cost-effective Solution: By eliminating the need for manual labour and reducing production time, infrared lamps help save on operational costs. Boost your bottom line without compromising quality or safety.

✅ Versatile Applications: Whether you're working with injection-moulded parts, 3D printed components, or extruded profiles, infrared lamps can effectively remove burrs and flash, leaving a smooth and polished finish.

✅ Environmentally Friendly: Infrared lamps consume less energy compared to other deburring methods, making them an eco-conscious choice. Reduce your carbon footprint while achieving exceptional results!

If you want to learn more about infrared lamps for plastic deburring or have any questions, feel free to reach out to us at info@victorylighting.co.uk