IR Reflectors

At Victory, we are always working on ways to improve performance and reduce energy costs. The use of both internal and external reflectors have significant advantages when using Infrared technology. Our external IR reflectors can be offered in a polished stainless steel or bespoke dichroic coating reflectors as well as using rigid silica materials.

We use these in our bespoke solutions, as replacements or part of an upgrade to any existing system you may have. For industrial processes such as PET bottle manufacturing, that require a fast, efficient source of heat, infrared lamps are the ideal solution. Victory infrared lamps are available with a reflector coating that directs that heat to where it's required, ensuring energy is used as efficiently as possible.

Product Benefits

Improved Efficiency

IR reflectors are designed to maximise the heat distribution, improving energy efficiency by directing more infrared radiation to the target, reducing heat loss.

Durable Construction

Built to withstand high temperatures and prolonged use, these reflectors provide consistent, long-lasting performance in demanding industrial applications.

Versatile Application

Suitable for a wide range of processes, including paint curing, drying, and heating, IR reflectors can be customised to meet specific needs, ensuring optimal results.

Heat Only Where It Is Needed

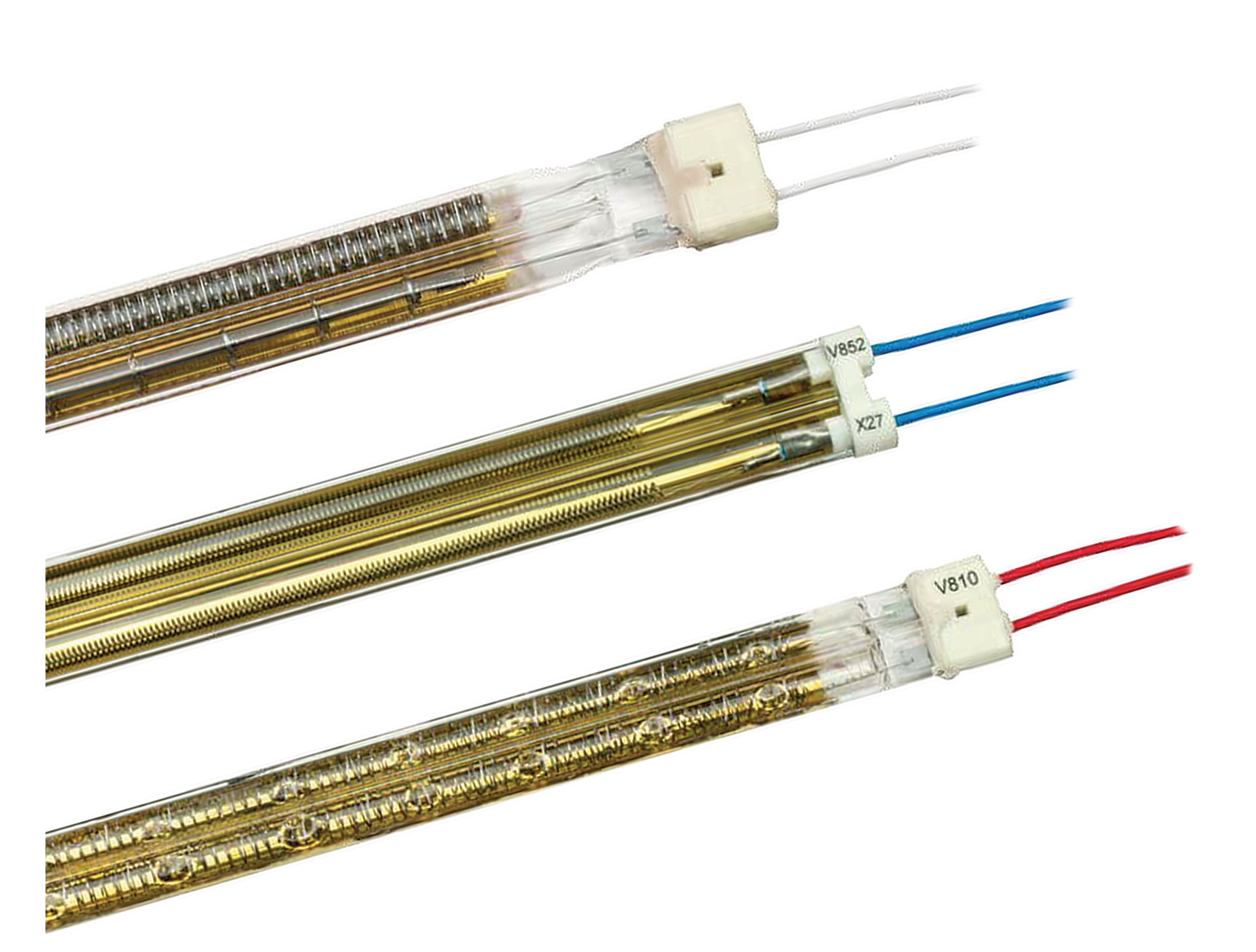

A bare lamp emits heat all around it circumference but usually heat needs to be directed to a particular location. This is achieved with a reflector. Separate external reflectors can be used but a reflector coating applied to the lamp itself gives the best efficiency and allows a simple compact heating unit to be constructed. Victory has a range of reflector lamps with different coatings to suit a wide variety of applications.

Big Energy Savings

During industrial processes such as PET bottle blowing or screen printing, infrared lamps are used to aid or speed up the process - for example, heating PET bottle pre-forms or flash curing inks on T-shirts. Processes such as these require focusing directly onto the material. In order to do this Victory applies reflector coating to the surface of the lamp, usually covering 180° of the surface area. This focuses energy in the desired direction, greatly increasing efficiency of the lamp by reducing wasted energy. Infrared reflector lamps can achieve big energy savings compared to lamps used without a reflector.