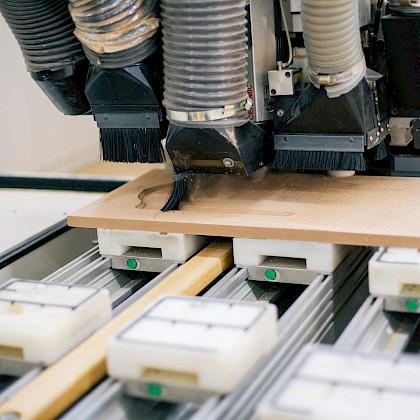

Wood Processing

Manufacturing using wood is very common and can require paint, lacquers, and various coatings to be applied and then subsequently dried. UV and IR sources can be used to dry or cure the particular paint or lacquer, but which one depends on the required finish. We typically deal with kitchen manufacturers and various furniture producers to help improve productivity and quality. Infrared ovens offer a dramatic time saving over hot air and especially over natural drying along with the advantage of uniform heat distribution.

Wood Manufacturing Processes

The use of wood in manufacturing is prevalent across a variety of industries, often requiring the application of paints, lacquers, and various coatings to enhance the material's appearance and durability. Once these finishes are applied, an efficient drying or curing process is essential to ensure the integrity and quality of the final product.

Drying and Curing with UV and IR Technologies

To achieve optimal results, manufacturers can utilise either UV (Ultraviolet) or IR (Infrared) sources for drying or curing the applied finishes. The choice between UV and IR technologies largely depends on the specific requirements of the desired finish, such as the type of coating used and the intended end result. Each method offers distinct advantages that can significantly impact productivity and quality.

At Victory, we primarily collaborate with kitchen manufacturers and various furniture producers to enhance their production processes. By integrating advanced drying technologies, we help these businesses improve both efficiency and the quality of their finished products.

Benefits of Infrared Ovens

Infrared ovens are particularly advantageous in wood manufacturing, offering substantial time savings compared to traditional hot air drying methods and especially natural drying processes. One of the standout features of infrared ovens is their ability to deliver uniform heat distribution, ensuring that every part of the wood surface receives consistent heat. This uniformity not only speeds up the drying process but also enhances the overall quality of the finish, reducing the risk of imperfections.

The rapid heating capabilities of infrared ovens also contribute to higher productivity levels, allowing manufacturers to complete their projects faster and meet market demands more effectively. By adopting these innovative technologies, companies in the wood manufacturing sector can achieve better outcomes while optimising their operational efficiency.

The integration of UV and IR drying technologies is transforming the wood manufacturing industry, providing manufacturers with the tools they need to enhance productivity and product quality. By focusing on innovative solutions like infrared ovens, Victory is committed to helping clients navigate the challenges of modern manufacturing while achieving superior results.