Can Manufacturing

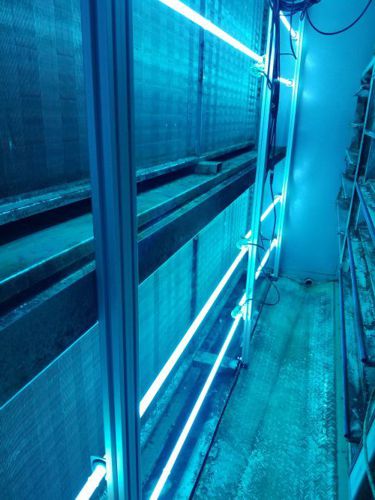

In the fast-paced world of can manufacturing, innovation plays a crucial role in meeting the ever-growing demands for efficiency, sustainability, and product quality. Among the most impactful advancements in this industry is the integration of ultraviolet (UV) lamp technology. UV lamps have become indispensable in various stages of the manufacturing process, offering precise and reliable curing solutions for coatings, inks, and adhesives.

The Growing Role of UV Lamps in Can Manufacturing

UV lamps are increasingly being adopted in can manufacturing plants around the world—and for good reason. This advanced technology is transforming the industry by offering significant benefits in efficiency, quality, sustainability, and cost-effectiveness, addressing key priorities for manufacturers and the environment alike.

Improved Efficiency

UV lamps enable the rapid curing and drying of coatings, adhesives, and inks used in can production. This accelerated process reduces production cycle times, increases output, and lowers energy consumption, ensuring manufacturers can meet high demand without compromising performance.

Consistent Quality

When it comes to achieving a flawless finish, UV lamps deliver consistently excellent results. Their precise and uniform curing capabilities eliminate issues such as uneven coatings or surface imperfections, resulting in finished products of the highest standard.

A Sustainable Choice

As the industry increasingly focuses on reducing its environmental impact, UV lamp technology is emerging as a key solution. By removing the need for solvent-based coatings, UV systems significantly reduce emissions of volatile organic compounds (VOCs). This not only helps to protect the environment but also supports the sustainability objectives of organisations such as Victory, which are committed to creating a greener future.

Cost-Effective Production

UV lamp technology also delivers notable cost savings for manufacturers. With faster drying times, lower energy requirements, and reduced waste from rejected cans, production becomes more efficient and economical, benefiting both manufacturers and the environment.

In summary, UV lamps are driving meaningful advancements in can manufacturing. By enhancing efficiency, ensuring quality, supporting sustainability, and lowering costs, this technology is shaping the future of the industry. It is clear that UV lamps are not just a step forward—they are a transformative innovation that is here to stay.