Specialists In

Infrared For Heat Processes

With costs continuing to rise, fully utilising the energy we consume is becoming more and more important.

Not only from a cost perspective, but also in reducing our carbon footprint. With many applications requiring heat at some point during the production process, its vital this is applied as effectively as possible to avoid wasting energy.

Some heating methods will consume vast amounts of energy ‘warming up’ as well as running continuously to avoid a repeat of the warming up process, which can take a lot of time. Many of these methods also use fossil fuels which are costly to run, require frequent maintenance and make up a large proportion of the world’s pollution.

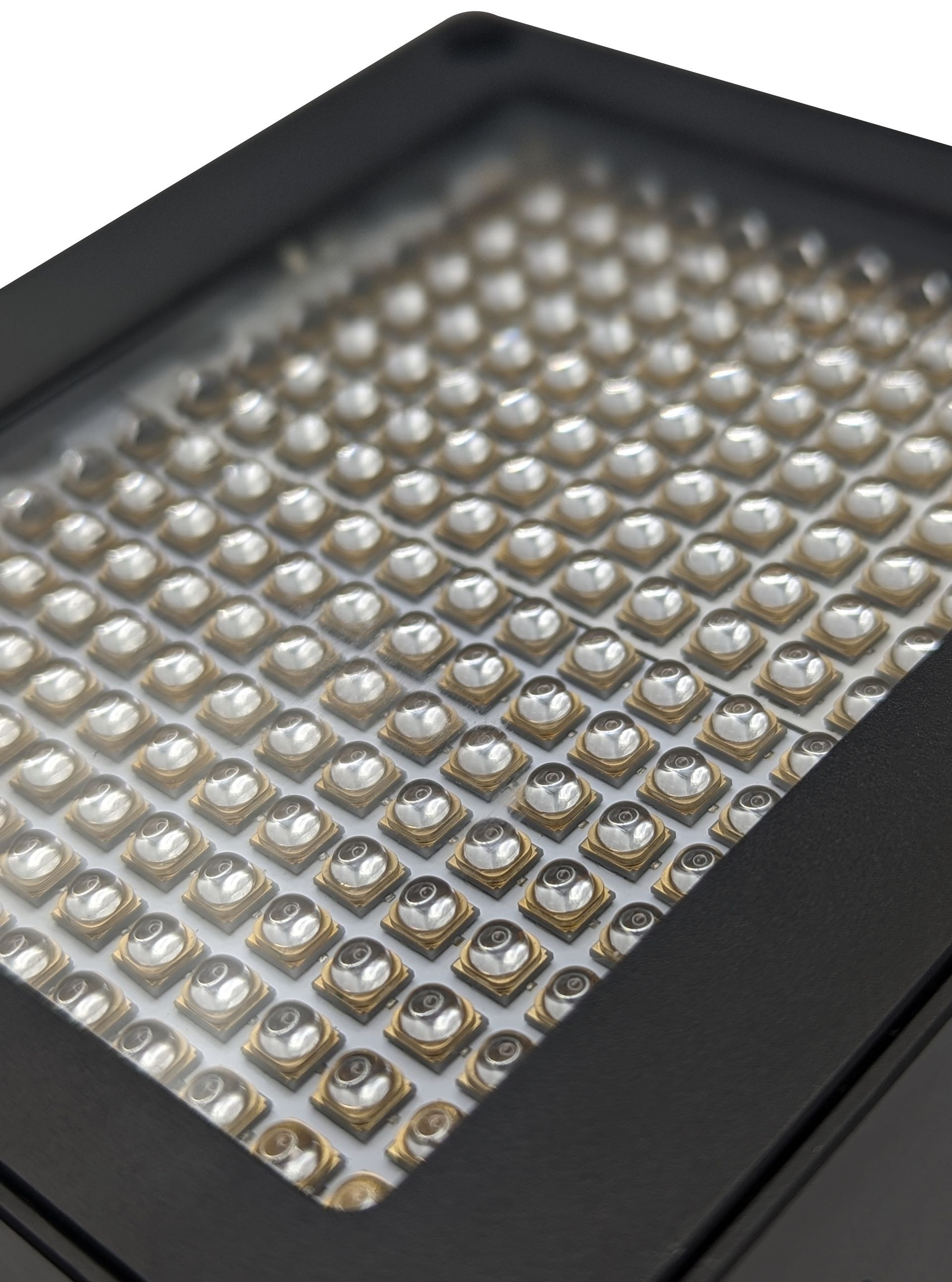

By using short wave IR which only requires electric, you can apply heat to exactly where it’s needed instantly. As the full output of these emitters can be achieved in less than 1 second, they only need be in operation for the amount of time required.

Furthermore, short wave emitters can be controlled and regulated so the output can be reduced when the maximum temperature may not be necessary. They also require minimal maintenance, offer long lifetimes of 5000 hours plus and are easy to change.

Short wave IR has continually proven to be a flexible and efficient heat source for heating/curing various types of materials. By utilising our expertise and testing facilities, we can advise and supply complete IR solutions for your application.

If you would like to see how using IR can improve your existing process or provide a solution to a new application, please feel free to contact us.

#infrared #heat